Basic materials of bolted aluminum electrolytic capacitor: anode foil, cathode foil, electrolytic paper, lead wire (Guide foil), cover plate, electrolyte, aluminum shell, explosion-proof valve, sealing ring, sleeve, gasket, etc

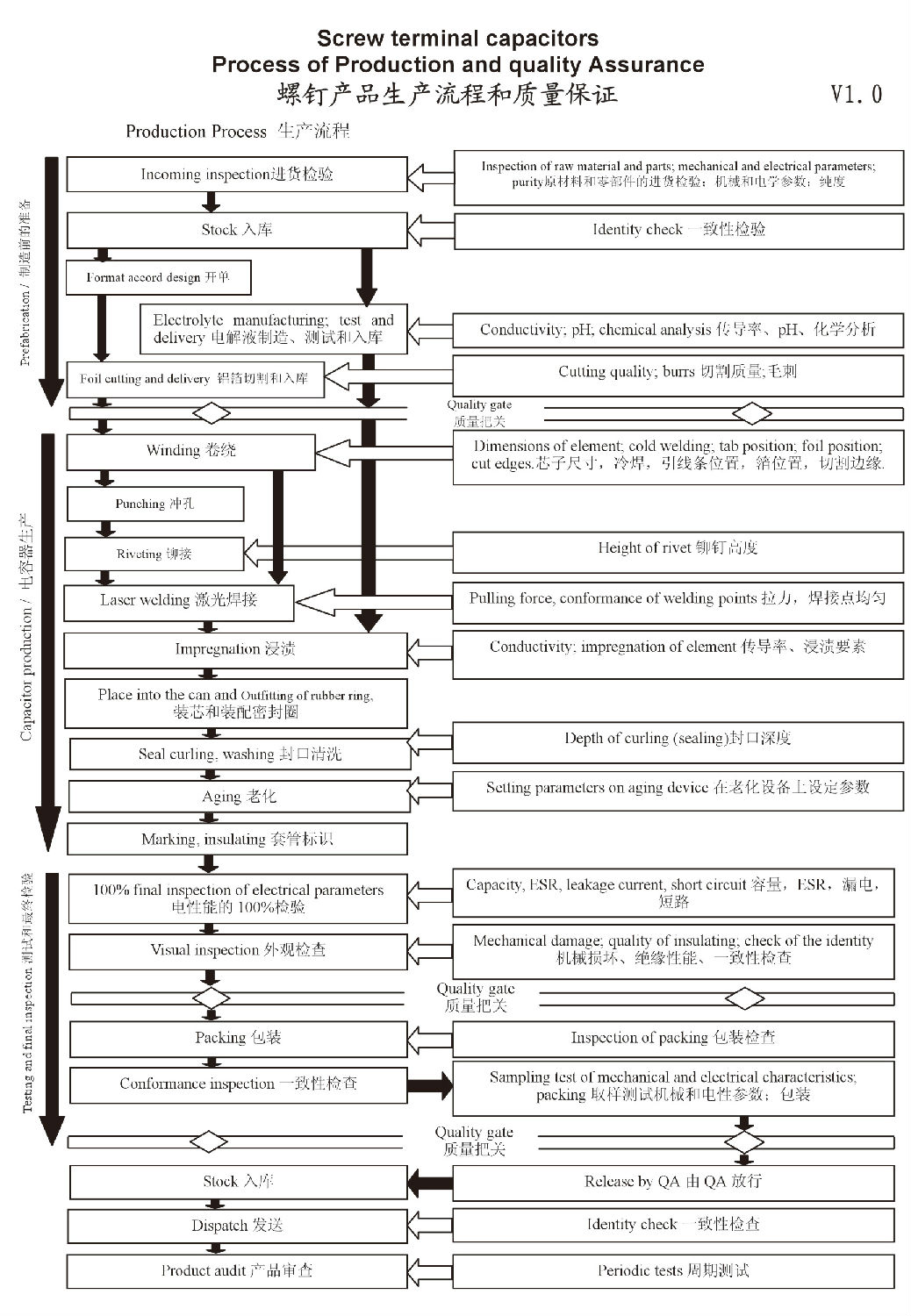

Production process of bolt electrolytic capacitor: cutting (anode foil, cathode foil and electrolytic paper are cut according to the specified width), winding (anode foil, cathode foil, electrolytic paper and lead wire (Guide foil) are rolled into core), laser riveting (lead strip and cover plate on the core are welded together to lead out the capacitance capacity), impregnation (electrolyte is immersed into the core), core assembly (core assembly) Put the capacitor into the aluminum shell, seal (seal the capacitor), aging (repair the oxide film on the surface of aluminum foil, eliminate the defective capacitor), bushing (put the capacitor on the label and insulate the capacitor), measurement (check whether the electrical performance of the capacitor meets the requirements), external inspection (check the appearance and size of the capacitor), packaging (pack the capacitor)

Kaiqijia capacitor has 25 years of electrolytic capacitor R & D experience of the technical team, the factory equipment is at the top level in the world, the degree of automation has reached more than 80%. It mainly produces cectn aluminum electrolytic capacitors with high power, large ripple current, long life, high voltage, high reliability and ultra small volume.

0086-13506000711

0086-13506000711

400V 6800μF screw capacitor

400V 6800μF screw capacitor 400V 2700μF screw capacitor

400V 2700μF screw capacitor 中文版

中文版