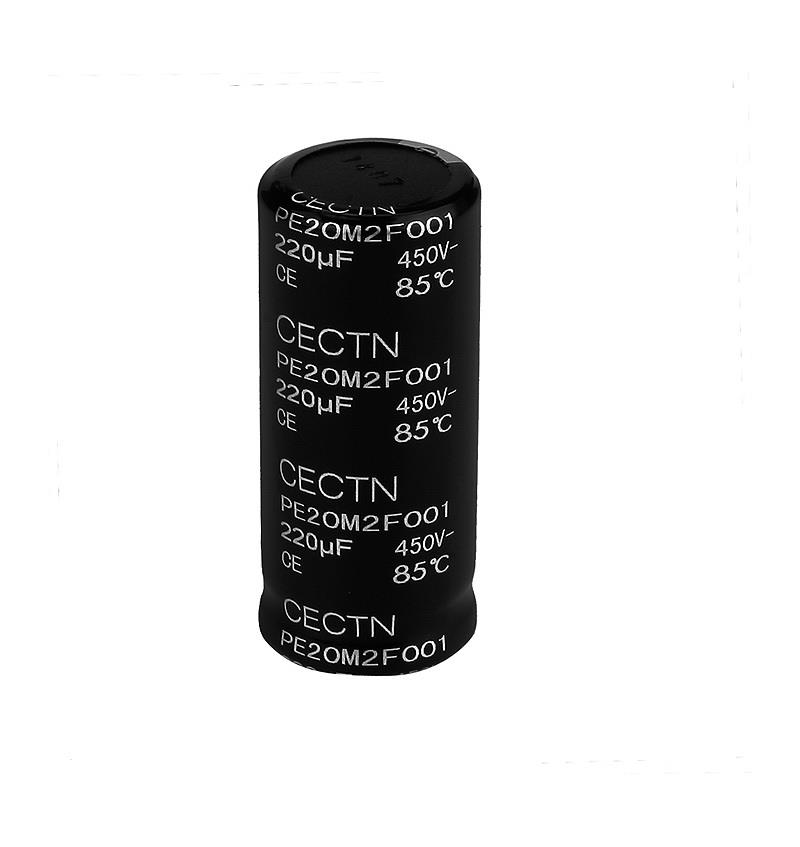

Kaiqijia capacitorFocus on the R & D and manufacturing of high voltage aluminum electrolytic capacitor for 25 years

- SCREW TERMINAL

- SNAP-IN

-

-

Annual output of 15 million pieces

China main supply 700V high voltage aluminum electrolytic capacitor manufacturer?

25 years focus on making electrolytic capacitors the best CECTN invested 60 million RMB,,covering an area of7,500 square meters

CECTN invested 60 million RMB,,covering an area of7,500 square meters

The modernized management process greatly improvesthe production efficiency

The modernized management process greatly improvesthe production efficiency

CECTN has more than 30 large-scaleequipment from abroad including cutting machine,More than 25 years experience in research and development in electrolytic capacitor

CECTN has more than 30 large-scaleequipment from abroad including cutting machine,More than 25 years experience in research and development in electrolytic capacitor

CECTN guarantee:only sell genuine capacitors, no dismantled capacitors, no used capacitors

CECTN guarantee:only sell genuine capacitors, no dismantled capacitors, no used capacitors

-

-

International quality and domestic price

Guarantee the quality of products from the source to ensure "zero" defects

Master core technology, electrolyte formula with independent intellectual property rights All the material of our capacitors are from top brand suppliers, such as Capchem, HEC, Zhejiang KAN

All the material of our capacitors are from top brand suppliers, such as Capchem, HEC, Zhejiang KAN

The longest service life of aluminum electrolytic capacitors can reach 30 years

The longest service life of aluminum electrolytic capacitors can reach 30 years

Which are widely used in industrial automation, Power, new energy, transportation, consumer electronics and other fields among domestic and abroad.

Which are widely used in industrial automation, Power, new energy, transportation, consumer electronics and other fields among domestic and abroad.

-

-

High-end imported equipment

Automation process up to 80% or moreProduction

capacity to meet large order productionThe aluminum foil cut by the famous brand cutting machine, which is from abroad, is enlarged to 150 times to inspect the burr

The aluminum foil cut by the famous brand cutting machine, which is from abroad, is enlarged to 150 times to inspect the burr

The aluminum foil cut by the famous brand cutting machine, which is from abroad, is enlarged to 150 times to inspect the burr

large-scale laser welding machine from abroad, laser welding leads after mechanical riveting, double insurance

large-scale laser welding machine from abroad, laser welding leads after mechanical riveting, double insurance

GE brand X-ray machine, omni-directional perspective inspection of the internal details

of the capacitor

GE brand X-ray machine, omni-directional perspective inspection of the internal details

of the capacitor

Automatic aging equipment from Germany can monitor each capacitor.

Automatic aging equipment from Germany can monitor each capacitor.

-

-

Customized production

Unique material number management for each customer

Meet your special customization needs with precise production The height and diameter of the products are customized according to customers' requirements

The height and diameter of the products are customized according to customers' requirements

The whole production process is controlled,Each product has its code, can trace the record,CECTN can be customized according to your request

The whole production process is controlled,Each product has its code, can trace the record,CECTN can be customized according to your request

Customization process: determine the parameters - sample trial - mass production - delivery

Customization process: determine the parameters - sample trial - mass production - delivery

-

-

Agent CECTN

Take advantage of market opportunities to create maximum profits

Now the country is continuing to hot investment in Open up a blank market, provide competitive factory prices, to create maximum profit

Open up a blank market, provide competitive factory prices, to create maximum profit

CECTN has become the most satisfied original supplier for many agents

CECTN has become the most satisfied original supplier for many agents

- Customer

- Honor

- About CECTN

- CECTN Photos

- Information

- College

- Q&A

CECTN capacitor won the qualification of

CECTN capacitor won the qualification of

Institutional investors enter CECTN

Institutional investors enter CECTN

315V1000uF bullhorn type aluminum electrolytic capacitor package size

315V1000uF bullhorn type aluminum electrolytic capacitor package size

What are the specifications of 315V1000uF bullhorn electrolytic capacitor?

What are the specifications of 315V1000uF bullhorn electrolytic capacitor?

200V470uF Bullhorn Electrolytic Capacitor Package Size

200V470uF Bullhorn Electrolytic Capacitor Package Size

What are the specifications of 200V470uF bullhorn electrolytic capacitors?

What are the specifications of 200V470uF bullhorn electrolytic capacitors?

-

Production process of bolt aluminum electrolytic capacitor

Production process of bolt aluminum electrolytic capacitor -

Basic materials of bolt aluminum electrolytic capacitor: anode foil, cathode foil, electrolytic paper, lead wire (Guide foil), cover plate, electrolyte, aluminum shell, explosion-proof valve, sealing ring, sleeve, gasket, etc To form a core, laser riveting (welding the lead strip on the core and the cover plate together to lead out the capacitance)

Basic materials of bolt aluminum electrolytic capacitor: anode foil, cathode foil, electrolytic paper, lead wire (Guide foil), cover plate, electrolyte, aluminum shell, explosion-proof valve, sealing ring, sleeve, gasket, etc To form a core, laser riveting (welding the lead strip on the core and the cover plate together to lead out the capacitance)

-

Package description of CECTN capacitor

Package description of CECTN capacitor -

In product packaging, kaiqijia pays great attention to environmental protection. This means that we only use environmentally friendly materials for packaging, and ensure the use of minimum materials. The packing quantity (bolts) of kaiqijia products are as follows: kaiqijia capacitors are packed in cartons and fixed with EPS upper and lower pads. EPS packaging material is light, has strong ability to absorb impact load, anti-static performance, better protect the product, ensure that the product is not damaged in the process of transportation, handling and use. Using standardized EU

In product packaging, kaiqijia pays great attention to environmental protection. This means that we only use environmentally friendly materials for packaging, and ensure the use of minimum materials. The packing quantity (bolts) of kaiqijia products are as follows: kaiqijia capacitors are packed in cartons and fixed with EPS upper and lower pads. EPS packaging material is light, has strong ability to absorb impact load, anti-static performance, better protect the product, ensure that the product is not damaged in the process of transportation, handling and use. Using standardized EU

0086-13506000711

0086-13506000711

700V 1000uF screw capacitor

700V 1000uF screw capacitor 700V 2200μF screw capacitor

700V 2200μF screw capacitor 600V 1200μF high voltage capacitor

600V 1200μF high voltage capacitor 600V 3300μF high voltage capacitor

600V 3300μF high voltage capacitor 600V 6800μF high voltage capacitor

600V 6800μF high voltage capacitor 600V 2200uF ultra high voltage

600V 2200uF ultra high voltage 600V 2700uF screw capacitor

600V 2700uF screw capacitor 600V 4700uF screw capacitor

600V 4700uF screw capacitor 500V 3300μF screw capacitor

500V 3300μF screw capacitor 500V 4700μF screw capacitor

500V 4700μF screw capacitor 500V 5600μF screw capacitor

500V 5600μF screw capacitor 450V 3900μF screw capacitor

450V 3900μF screw capacitor 450V 4700μF screw capacitor

450V 4700μF screw capacitor 450V 10000μF screw capacitor

450V 10000μF screw capacitor 450V 8200uF screw capacitor

450V 8200uF screw capacitor 450V 6800uF screw capacitor

450V 6800uF screw capacitor 450V 3900uF Extraordinary life

450V 3900uF Extraordinary life 400V 10000μF screw capacitor

400V 10000μF screw capacitor 400V 4700μF screw capacitor

400V 4700μF screw capacitor 400V 3900uF screw capacitor

400V 3900uF screw capacitor 400V 8200uF screw capacitor

400V 8200uF screw capacitor 400V 3300μF screw capacitor

400V 3300μF screw capacitor 400V 2200μF screw capacitor

400V 2200μF screw capacitor 400V 2700μF screw capacitor

400V 2700μF screw capacitor 400V12000uF screw capacitor

400V12000uF screw capacitor 400V6800uF High ripple resistance capacitor

400V6800uF High ripple resistance capacitor 400V15000uF Extraordinary life

400V15000uF Extraordinary life 400V15000uF high capacity capacitor

400V15000uF high capacity capacitor 400V5600uF compact capacitor

400V5600uF compact capacitor 400V3900uF mini capacitor

400V3900uF mini capacitor 400V4700uF mini capacitor

400V4700uF mini capacitor 400V 6800μF screw capacitor

400V 6800μF screw capacitor 350V 22000μF screw capacitor

350V 22000μF screw capacitor 350V 15000μF screw capacitor

350V 15000μF screw capacitor 350V 6800μF screw capacitor

350V 6800μF screw capacitor 300V 27000μF screw capacitor

300V 27000μF screw capacitor 300V 18000μF screw capacitor

300V 18000μF screw capacitor 250V 15000μF screw capacitor

250V 15000μF screw capacitor 250V 22000μF screw capacitor

250V 22000μF screw capacitor 250V 4700μF screw capacitor

250V 4700μF screw capacitor 500V 390μF snap-in capacitor

500V 390μF snap-in capacitor 500V 470μF snap-in capacitor

500V 470μF snap-in capacitor 500V 330μF snap-in capacitor

500V 330μF snap-in capacitor 450V 220μF solder pin type

450V 220μF solder pin type 450V 390μF snap-in capacitor

450V 390μF snap-in capacitor 450V470uf snap-in capacitor

450V470uf snap-in capacitor 450V 1000μF snap-in capacitor

450V 1000μF snap-in capacitor 400V 270μF snap-in capacitor

400V 270μF snap-in capacitor 400V1000uf snap-in capacitor

400V1000uf snap-in capacitor 400V820uf snap-in capacitor

400V820uf snap-in capacitor 400V 820μF snap-in capacitor

400V 820μF snap-in capacitor 400V 560μF snap-in capacitor

400V 560μF snap-in capacitor 400V1000uf compact capacitor

400V1000uf compact capacitor 350V 470μF solder pin type

350V 470μF solder pin type 350V 1000μF snap-in capacitor

350V 1000μF snap-in capacitor 350V 1200μF snap-in capacitor

350V 1200μF snap-in capacitor 315V 470μF snap-in capacitor

315V 470μF snap-in capacitor 315V 1000μF snap-in capacitor

315V 1000μF snap-in capacitor 250V 1500μF snap-in capacitor

250V 1500μF snap-in capacitor 250V 2200μF snap-in capacitor

250V 2200μF snap-in capacitor 250V 1000μF snap-in capacitor

250V 1000μF snap-in capacitor 200V 470μF snap-in capacitor

200V 470μF snap-in capacitor 200V 1800μF snap-in capacitor

200V 1800μF snap-in capacitor 200V 1200μF snap-in capacitor

200V 1200μF snap-in capacitor

CECTN invested 60 million RMB,,covering an area of7,500 square meters

CECTN invested 60 million RMB,,covering an area of7,500 square meters

CECTN Technology Co., Ltd.

CECTN Technology Co., Ltd.

Basic materials of bolt aluminum electrolytic capacitor: anode foil, cathode foil, electrolytic paper, lead wire (Guide foil), cover plate, electrolyte, aluminum shell, explosion-proof valve, sealing ring, sleeve, gasket, etc To form a core, laser riveting (welding the lead strip on the core and the cover plate together to lead out the capacitance)

Basic materials of bolt aluminum electrolytic capacitor: anode foil, cathode foil, electrolytic paper, lead wire (Guide foil), cover plate, electrolyte, aluminum shell, explosion-proof valve, sealing ring, sleeve, gasket, etc To form a core, laser riveting (welding the lead strip on the core and the cover plate together to lead out the capacitance) 中文版

中文版