Due to the special properties of the aluminum oxide layer (which also acts as the insulating layer), even after the DC voltage is applied for a long time, a small current will continue to over flow, which is called leakage current. The smaller the leakage current is, the better the insulation performance is.

1. Time and temperature characteristics of leakage current

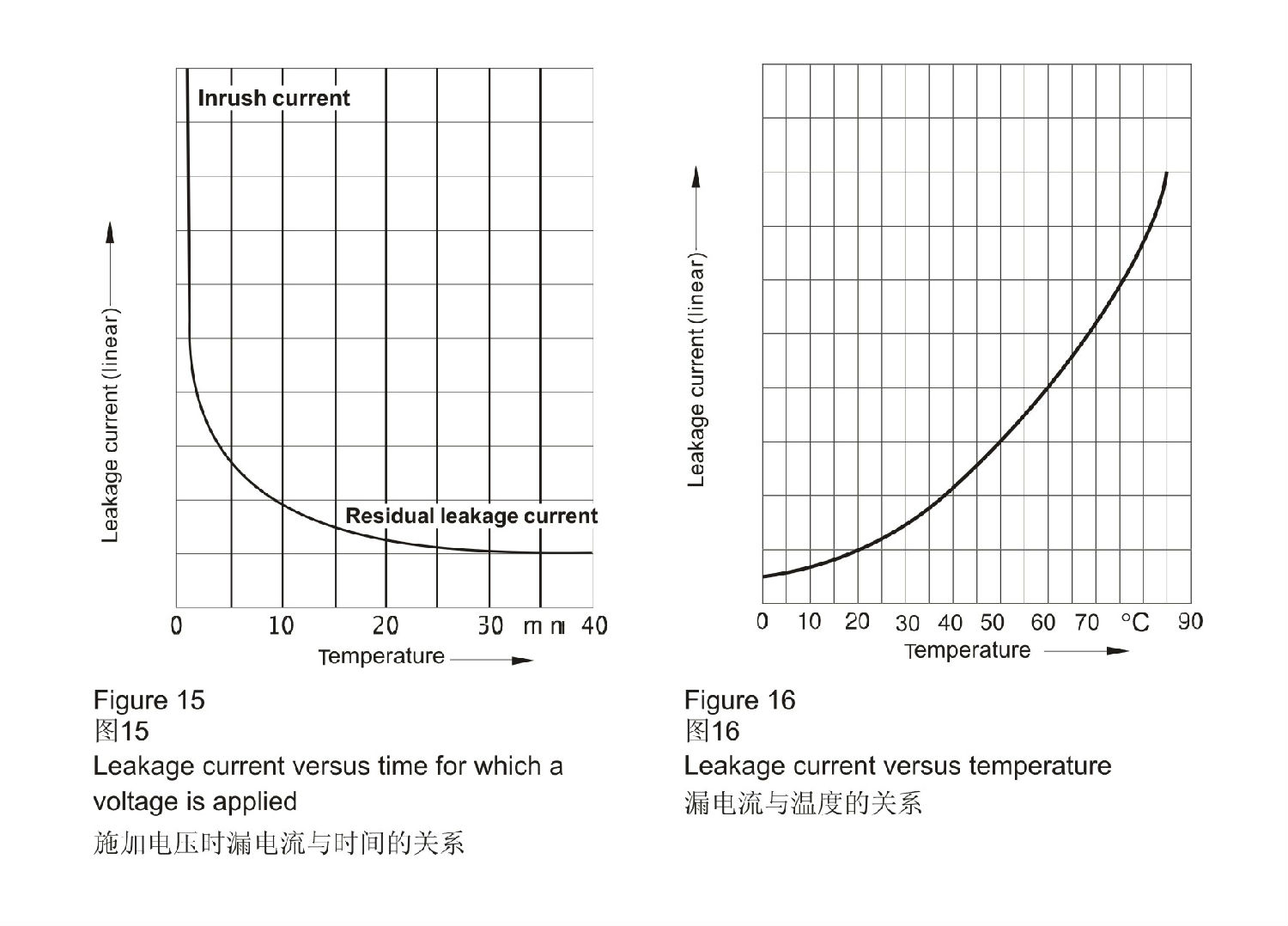

As shown in Figure 15, there is a strong leakage current in the first few minutes when the voltage is applied to the aluminum electrolytic capacitor, especially when no overvoltage is applied during long-term storage. During continuous operation, the leakage current decreases to an almost constant "steady state" value.

The temperature characteristic of leakage current is shown in FIG. 16, taking the capacitor with 85 ℃ temperature as an example.

2. Characteristics of leakage current and voltage

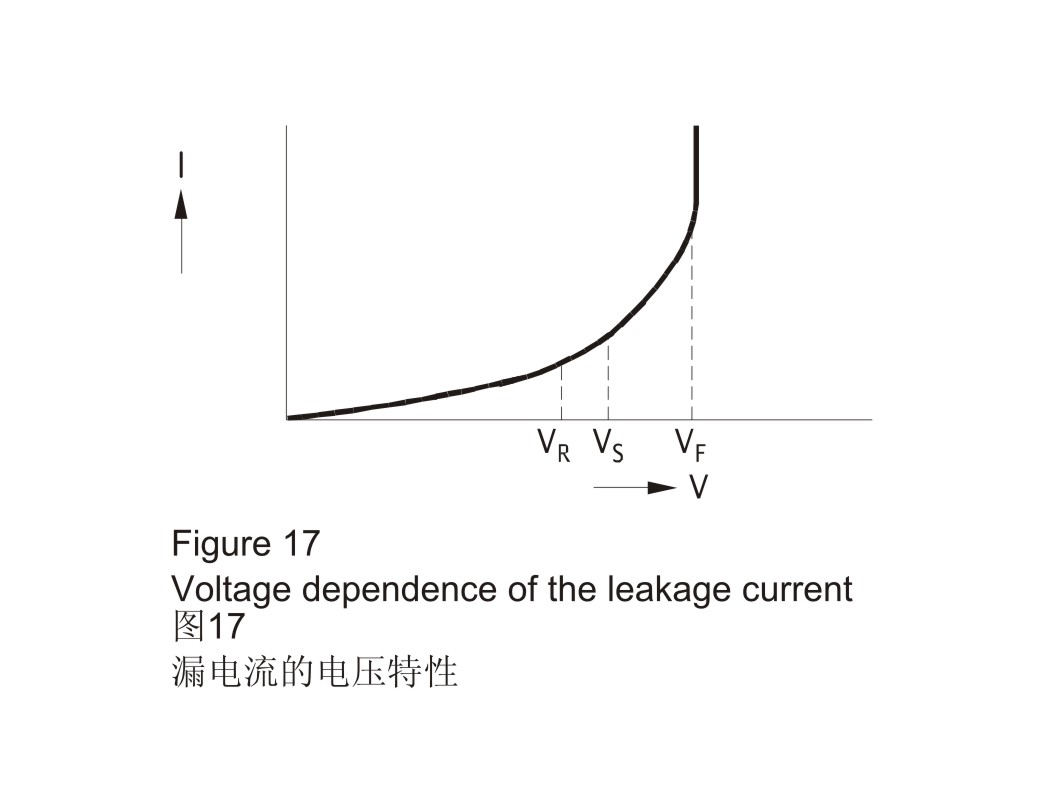

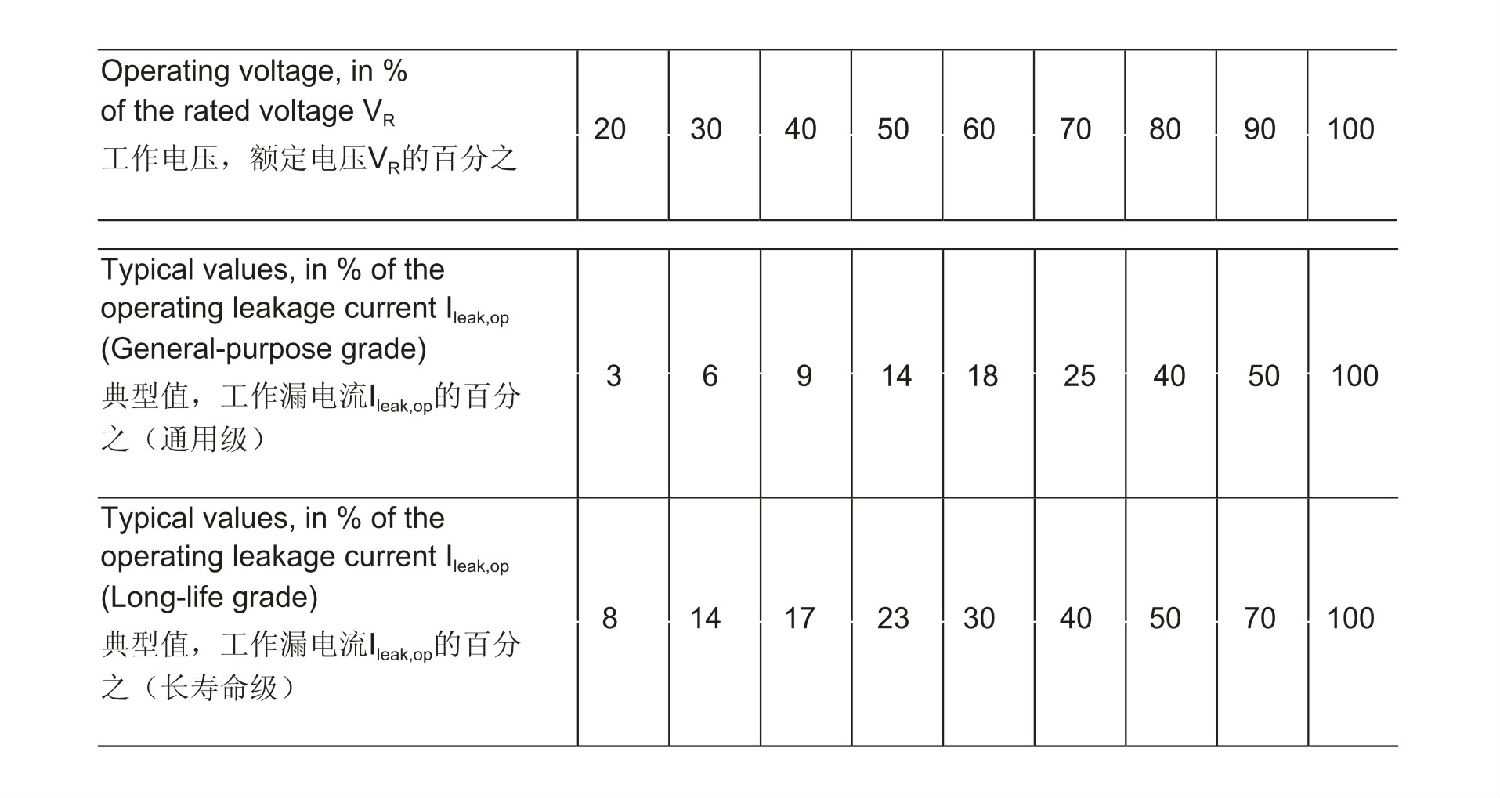

At constant temperature, the relationship between leakage current and applied voltage is shown in Figure 17.

3. Working leakage current ileak, Op

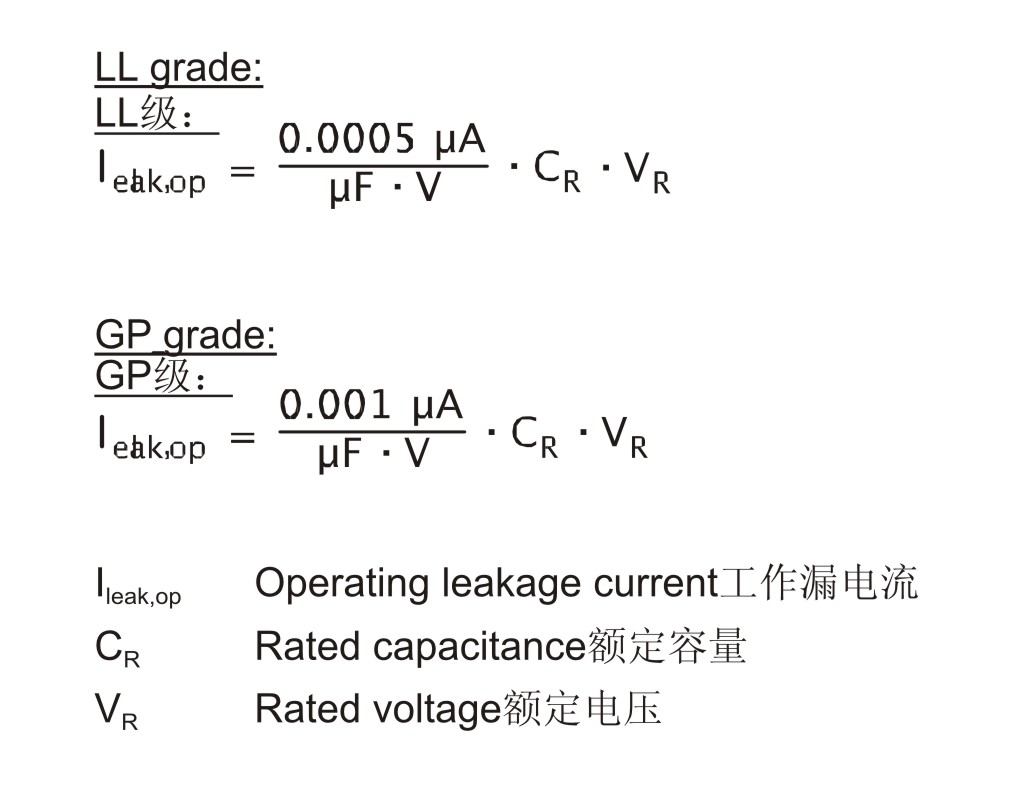

Working leakage current refers to the steady-state current under continuous working condition. The ileak, Op of kaiqijia electrolytic capacitor can be calculated by the following formula:

The above results were obtained at rated voltage VR and 20 ℃.

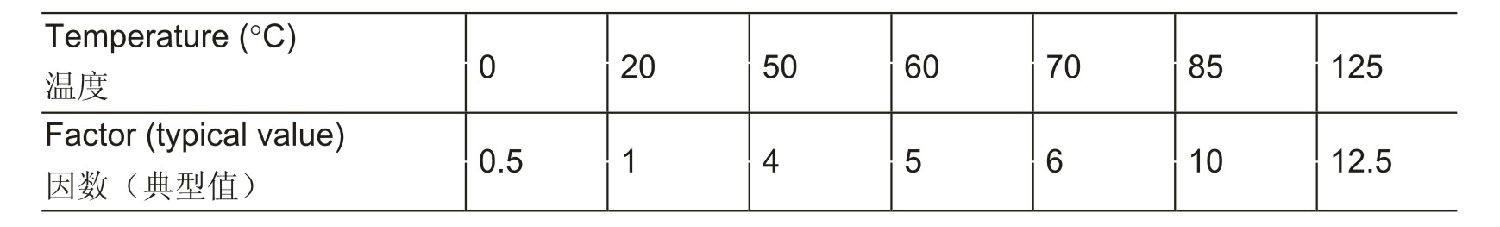

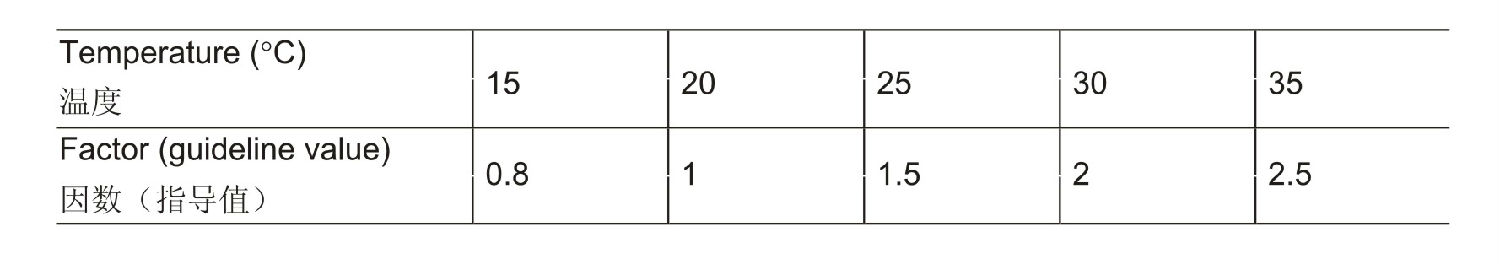

The results obtained at 20 ℃ must be multiplied by the following factors to obtain the temperature characteristics of the operating leakage current of general purpose and long life capacitors.

When the actual working voltage is lower than the rated voltage, the working leakage current will be greatly reduced

4. Acceptance test of leakage current ileak, Op

Because the leakage current varies with time and temperature, it is necessary to define the reference value of measurement time and reference temperature. According to en130300, the leakage current to be measured shall be measured at 20 ℃ after applying the rated voltage for 5 minutes. The following formula applies:

0.06c. V (μ a) or 5mA (example: bolt type product)

The acceptance test of leakage current can be carried out between 15 ℃ and 35 ℃. The permissible limits shall then be multiplied by the following conversion factors, with reference to the value at 20 ℃

5. Re formation

According to IEC 60384-4, before the acceptance test, aluminum electrolytic capacitors must be reconstituted. This pretreatment step aims to ensure the same initial conditions when comparing and evaluating different products.

For this purpose, the rated voltage will be applied to the capacitor through a series resistance of about 100 Ω (VR ≤ 100V DC) or about 1000 Ω (VR < 100V DC) for one hour.

Then, the capacitor was stored at 15 ~ 35 ℃ for 12 ~ 48 hours. Then, the leakage current must be measured within 48 hours at the latest.

If the capacitor meets the leakage current requirement without pretreatment, this step can be ignored.

6. Leakage current characteristics without voltage application (no voltage storage)

When the electrolytic capacitor is stored without external voltage, the oxide layer may degrade, especially at high temperature. Because there is no leakage current to transmit cations to the anode, the oxide layer can not be regenerated. This results in a stronger current than the normal leakage current when the voltage is applied for the first time after long-term storage. However, due to the regeneration of oxide layer during use, the leakage current will gradually decrease to normal level.

Aluminum electrolytic capacitors can be stored for at least two years without voltage application (≤ 100 VR one-way lead products for one year). Assuming that the storage period is not exceeded, the stored capacitor can work directly under the rated voltage. In this case, the steps described in the chapter "recast" can be omitted.

When designing the application circuit, it must be noted that the leakage current may be hundreds of times higher than the normal level in the first few minutes of loading the power supply.

When the capacitor is stored for 2 years, whether the circuit allows a higher initial leakage current is often decisive. Circuits stored with capacitors for more than two years shall be trouble free for one hour. This usually allows the capacitor to regenerate and then continue to be stored.

0086-13506000711

0086-13506000711

400V 6800μF screw capacitor

400V 6800μF screw capacitor 400V 2700μF screw capacitor

400V 2700μF screw capacitor 中文版

中文版