1. Installation position of bolt aluminum electrolytic capacitor

During the working period, the leakage current will continue to flow through the aluminum electrolytic capacitor, leading to electrolysis. On the one hand, the oxygen produced by electrolysis will regenerate the insulation layer, but on the other hand, the released hydrogen will generate air pressure inside the capacitor.

When the air pressure reaches a certain level, the safety valve on the cover plate will release the gas, so as to prevent the explosion of the capacitor due to the high air pressure during overload.

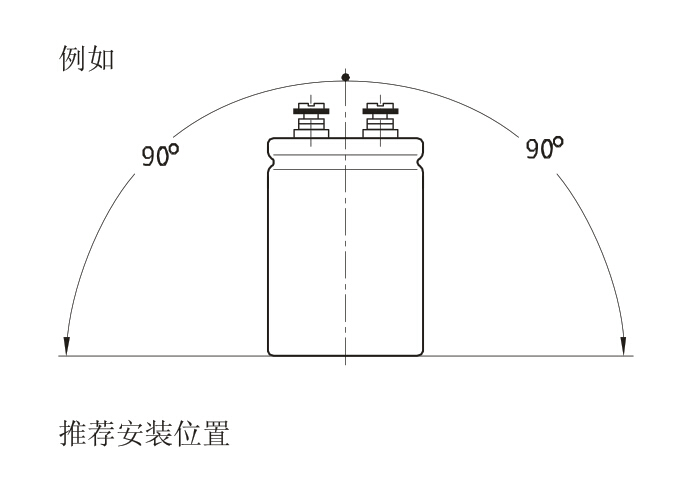

In order to prevent electrolyte leakage during gas release, the capacitor terminal (safety valve end) shall not be installed upside down. In order to avoid reverse installation of capacitor safety valve, the installation position shown in the figure below is recommended.

It is recommended that the terminals be installed facing up, especially when the capacitor is fixed by bolts or terminals near the bottom.

In horizontal installation, the safety valve is at "12" point.

In addition to the above recommended installation position, other methods will not directly damage the capacitor, but may cause a series of indirect damage in operation due to electrolyte leakage during the exhaust process.

2. Packaging and adhesive of aluminum electrolytic capacitor

The encapsulation compound or adhesive must be free of halogen or other corrosive substances.

The encapsulation or adhesive material must not damage the function of the capacitor safety valve.

Encapsulation compounds or adhesives may heat the capacitor during processing. If possible, do not exceed the temperature.

Insulation may be damaged if the temperature exceeds 150 ℃.

According to the duration, the temperature rise in the process may cause the leakage current to rise when the capacitor is first powered on, but it will not affect the life of the capacitor.

Due to the poor thermal conductivity of encapsulation compounds, the thermal calculation effect of capacitors is usually affected. Continuous heating will shorten the life of the capacitor.

When heated, the packaging compound may apply pressure to the capacitor, which should not exceed 20 bars.

PVC materials of heat shrinkable pipes may contain some substances that will react violently with encapsulation compounds or adhesives after long-term operation.

If viscose is the only mechanical fixation method, the mechanical stability of heat shrinkable tube is the decisive factor of capacitance stability coefficient.

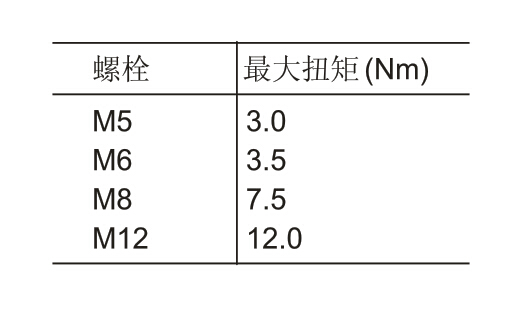

3. Installation torque

Do not exceed the maximum torque listed in the table below when locking bolts or installing nuts.

4. Welding

Too long welding time or over temperature will affect the capacitance performance and damage the insulating sleeve.

Avoid touching insulating sleeve with soldering iron.

The welding conditions (preheating, welding temperature and soaking time) shall be within the scope specified in the product specification.

5. Detergent

If the halogenated hydrocarbon comes into contact with the electrolytic capacitor, it will cause serious damage. The relevant solvent can dissolve or decompose the insulation skin and reduce the insulation performance to below the allowable range. The capacitor seal will also be affected and expand, and the relevant solvent can even pass through the seal, leading to premature damage of aluminum electrolytic capacitor.

Therefore, measures must be taken to prevent electrolyte from contacting with solvent when using halogenated hydrocarbon to clean the PCB surface or remove flux residue after soldering components to PCB. If it is not possible to prevent the capacitor from contacting the solvent, halogen-free solvent must be used to avoid damage.

Halogen free solvent

Alcohol (methylated alcohol)

Propane alcohol

Isopropanol

butanol

Propane glycol

Diethyl glycol

Critical solvent

The following table shows the critical halogenated hydrocarbons and other solvents commonly used in electronic industry, sometimes used alone, sometimes mixed with other solvents.

Trifluorochloroethane (trade names such as Freon, kaltron and frigene)

Trichloroethylene

Trichloroethane (trade name e.g. chloroethane, Wacker chlorovinegar 3 × 1)

Tetrachloroethylene (trade name such as per)

Methylene dichloride

Chloroform

Tetrachloromethane

acetone

Butanone

ethyl acetate

Butyl acetate

However, the existing PCB cleaning equipment often uses halogenated solvents, but it is designed to achieve thorough cleaning in a short time (four cabin ultrasonic cleaning process). In addition, all processes ensure that there is no solvent residue on the cleaning element.

This shows that when the following conditions are met, the usual precautions for using halogenated cleaner for aluminum electrolytic capacitor are followed:

1. The cleaning time of each cabin shall not exceed one minute.

2. In the final cleaning stage, a single solvent vapor must be used, and the temperature must be light rain or equal to 50 ℃

3. After the cleaning process, be sure to dry sufficiently immediately to evaporate any condensed residual solvent.

4. Contaminated cleaners must be replaced regularly in accordance with the manufacturers and statutory regulations.

If you have any problems or questions in the installation and use of aluminum electrolytic capacitors, please feel free to contact kaiqijia capacitor at 400-00-23930

0086-13506000711

0086-13506000711

400V 6800μF screw capacitor

400V 6800μF screw capacitor 400V 2700μF screw capacitor

400V 2700μF screw capacitor 中文版

中文版