What is the basic structure of aluminum electrolytic capacitor?

Scan!

Scan!What is the basic structure of aluminum electrolytic capacitor?

Because the working principle of aluminum electrolytic capacitor depends partly on the electrochemical process, the product occupies a special position in various series of capacitors.

Based on the advantages of high volume efficiency (i.e. capacitance per unit volume), aluminum electrolytic capacitors are widely used. This feature not only makes the capacitance of the product as high as farad, but also can withstand large ripple current. In addition, the product has reliable quality and superior cost performance.

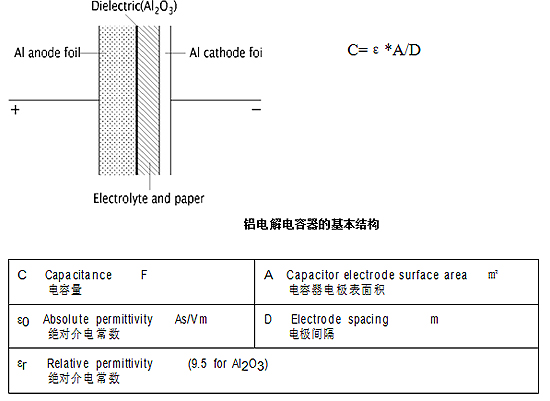

Like other capacitors, aluminum electrolytic capacitors have two conductive electrodes separated by an insulating layer. One electrode (anode) is formed by aluminum foil with expanded surface area, and an insulating layer is formed on its surface by an oxide layer (Al2O3). Different from other capacitors, the counter electrode (cathode) of aluminum electrolytic capacitor is conductive liquid working electrolyte. Another layer of aluminum foil, the so-called cathode foil, has a larger contact area and can transmit current to the electrolyte.

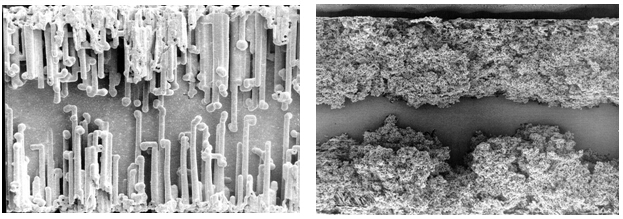

The anode of aluminum electrolytic capacitor is high purity aluminum foil, and its effective surface area is greatly expanded (up to 200 times) by electrochemical corrosion, so that the maximum possible capacitance value can be obtained. The corrosion mode and degree are different, which depends on the specific process requirements. Etched foil achieves a very compact aluminum electrolytic capacitor size, which is almost the only form currently used. To a certain extent, the electrical characteristics of aluminum electrolytic capacitors using original foil (non corrosive foil) are better, but the volume of the related capacitors is larger, which is limited to some special applications at present.

The insulation layer of aluminum electrolytic capacitor is formed by anodic oxidation, and the aluminum oxide layer is formed on the aluminum foil. The thickness of the layer increases with the increase of formation voltage, and the ratio is nearly 1.2 nm / v. Even if the capacitor is very high voltage resistant, its oxide layer will not exceed 1m, so that the electrode spacing can be very small. This is one of the reasons for achieving high volume efficiency (in comparison, the minimum thickness of paper insulation is 6-8? M). During the formation process, the crust thickness of the small pits on the etched foil is partly affected by the formation voltage. Based on this effect, the final operating voltage range must be considered when etching aluminum foil.

The insulation layer of aluminum electrolytic capacitor is formed by anodic oxidation, and the aluminum oxide layer is formed on the aluminum foil. The thickness of the layer increases with the increase of formation voltage, and the ratio is nearly 1.2 nm / v. Even if the capacitor is very high voltage resistant, its oxide layer will not exceed 1m, so that the electrode spacing can be very small. This is one of the reasons for achieving high volume efficiency (in comparison, the minimum thickness of paper insulation is 6-8? M). During the formation process, the crust thickness of the small pits on the etched foil is partly affected by the formation voltage. Based on this effect, the final operating voltage range must be considered when etching aluminum foil.

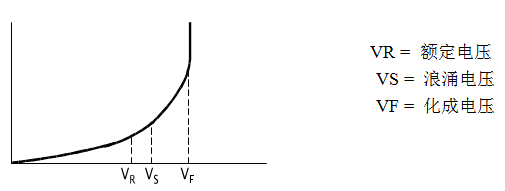

The insulation of the oxide layer changes with the change of voltage, resulting in the sharp increase of current with the increase of voltage, as shown in the characteristic curve

When the formation voltage VF is exceeded, a large amount of new gas will be produced in the formation process, thus generating heat. The same phenomenon is also reflected in the curve above. In order to realize the high reliability operation of capacitor, the rated voltage VR is defined as the voltage corresponding to the quasi linear part of the curve. Since the capacitor is only affected by the surge voltage vs in a short period of time, the VS is between the rated voltage and the formation voltage. The difference between formation voltage and working voltage, which is called over anodization, has a positive impact on the reliability of capacitors. High over anodization makes it possible to produce highly stable capacitors (in accordance with IEC 60384 – 1 long life class).

Since the cathode of aluminum electrolytic capacitors is liquid, they are also called "wet" or "non solid" capacitors. The advantage of the electrolyte is that it can be filled with corrosion pits, so it can be perfectly combined with the anode structure.

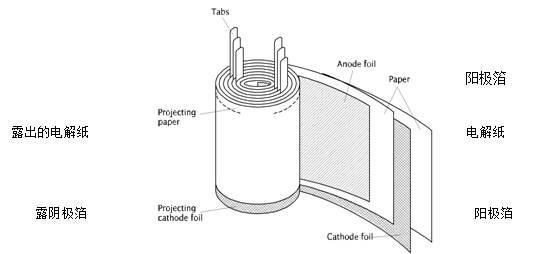

The two layers of aluminum foil are insulated by electrolytic paper, which plays different roles here. It is not only the container of electrolyte - the electrolyte is stored in the gap of absorbent paper - but also can prevent electrical short circuit and ensure the required insulation strength between anode foil and cathode foil.

The above aluminum electrolytic capacitor can work normally only when the connection is correct, and the positive voltage needs to be connected to the formed aluminum foil (or anode), and the negative voltage needs to be connected to the cathode foil. If the connection is reversed, it will lead to the electrochemical process and lead to the formation of an insulating layer on the cathode foil. In this case, high heat will be generated inside the capacitor, and gas will be emitted, causing damage to the capacitor. Secondly, with the increase of the thickness of the oxide layer, the capacitance of the cathode in series with the anode capacitance will be greatly reduced, thus the total capacitance will be greatly reduced.

Therefore, the aluminum electrolytic capacitor with the above basic structure is only suitable for DC application. The DC voltage may be a waveform voltage, that is, the DC voltage superimposed with the AC voltage, but the positive pole of the voltage must be connected to the anode. Such capacitors are polar and can be used in most applications.

As mentioned above, polarity capacitors do not support reverse voltage connection. If the voltage is reversed and the voltage value is not more than 1.5V, short-term operation can be allowed, because the formation of damaged cathode oxide layer only starts when the voltage reaches 1.5V (because there is a layer of air oxide on the cathode foil, and its breakdown voltage is close to 1.5V).

同类文章排行

- Tangent of loss angle of electrolytic capacitor

- Production process of bolt aluminum electrolytic capacitor

- Definition of capacitance of electrolytic capacitor

- Material number description of CECTN aluminum electrolytic capacitor

- How will capacitors develop in the new energy era

- Package description of CECTN capacitor

- Service temperature of aluminum electrolytic capacitor

- Precautions for capacitor use

- Definition of capacitor voltage in aluminum electrolysis

- Calculation formula of service life of aluminum electrolytic capacitor

最新资讯文章

- 250V 4700μF screw capacitor

- 250V 22000μF screw capacitor

- 250V 15000μF screw capacitor

- 300V 18000μF screw capacitor

- 300V 27000μF screw capacitor